CNRS / ESYCOM: Energy harvesting with TENG

Four-week research internship at the CNRS / ESYCOM Laboratory (UMR CNRS 9007).

Supervisor: Prof. Philippe Basset.

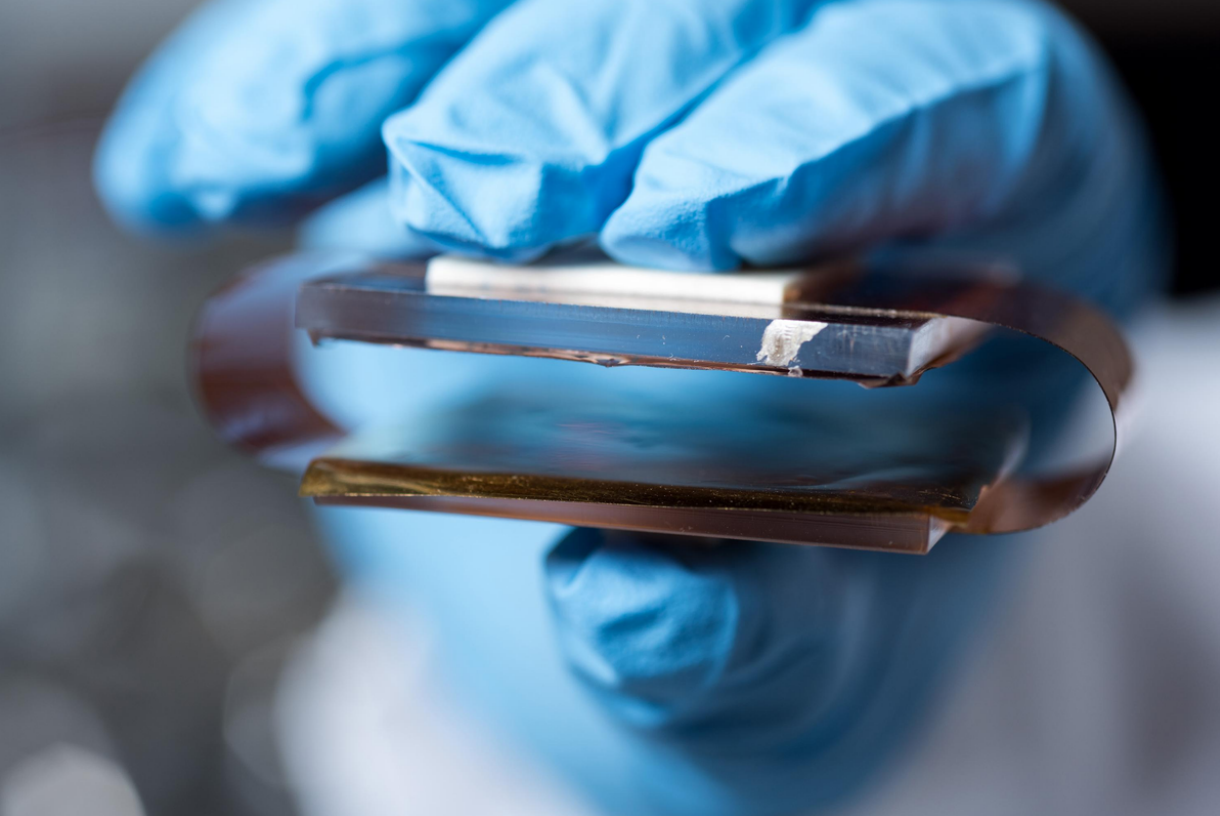

Goal: simulate and validate a conditioning circuit for a Triboelectric Nanogenerator (TENG) that harvests mechanical energy (vehicle pass) and powers a Bluetooth transmission to a smartphone.

Reference: Nature Communications: “Employing a MEMS plasma switch for conditioning high-voltage kinetic energy harvesters”.

Nature article Report (PDF, in french) Slides (PPTX)

Context & Objective

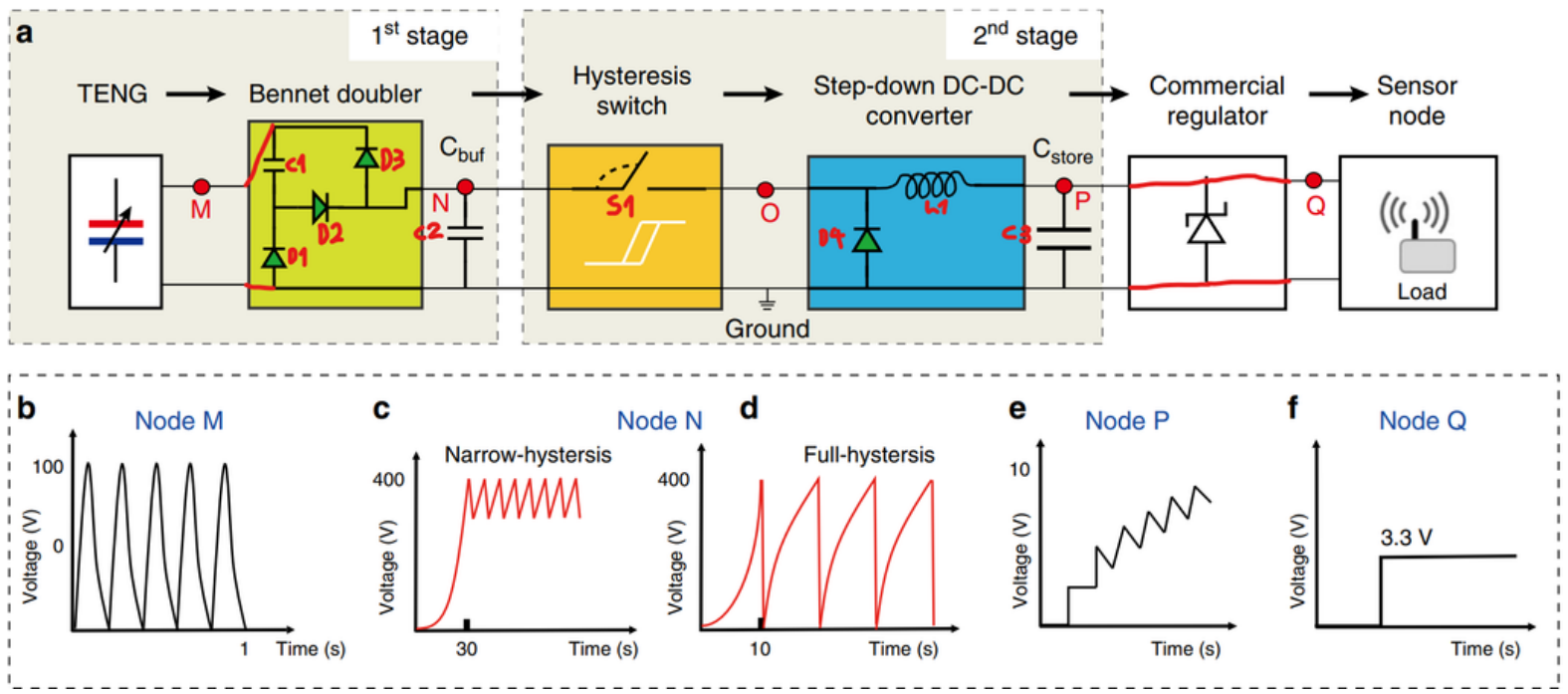

TENG devices deliver high-voltage, low-current, pulsed outputs, not directly usable by electronics. The project adapts the two-stage chain from the paper: Bennet doubler → hysteresis switch → step-down DC-DC → regulator to store energy and supply ~3.3–3.6 V for a Bluetooth node.

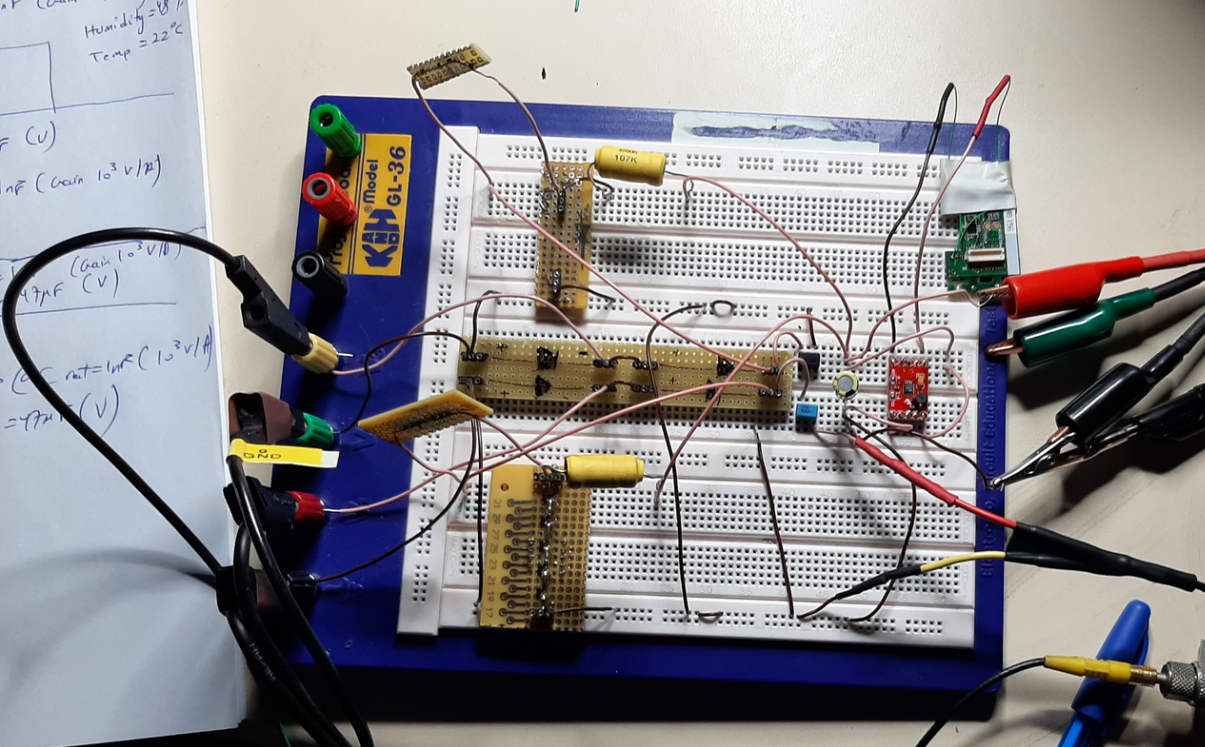

My task was to compare circuit options, model them in LTSpice, and verify behaviors on a bench prototype and on-site tests.

Approach

- Modeling. Full path in LTSpice with parametric sweeps of:

- Bennet doubler capacitors/diodes (charging efficiency)

- Hysteresis thresholds (switching stability & charge bursts)

- Storage & DC-DC (ripple vs. time-to-start)

- Measurement. Prototype assembled; node voltages (M, N, P, Q) captured on scope.

- Field test. Validation with a vehicle pass over the ramp; alignment/friction tuned for repeatability.

Selected results

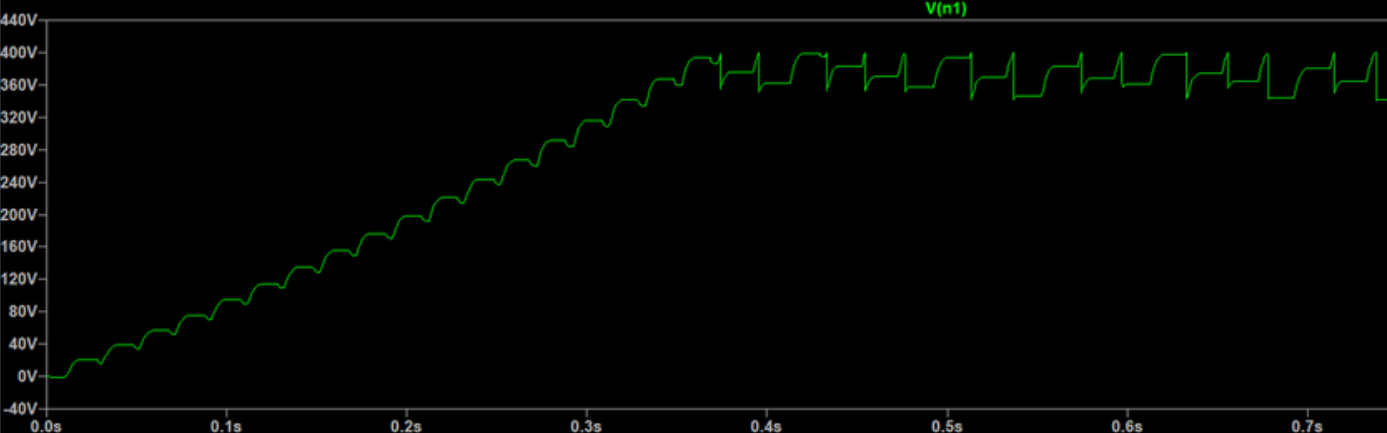

- Node N shows the expected sawtooth charge then burst discharge when the hysteresis triggers.

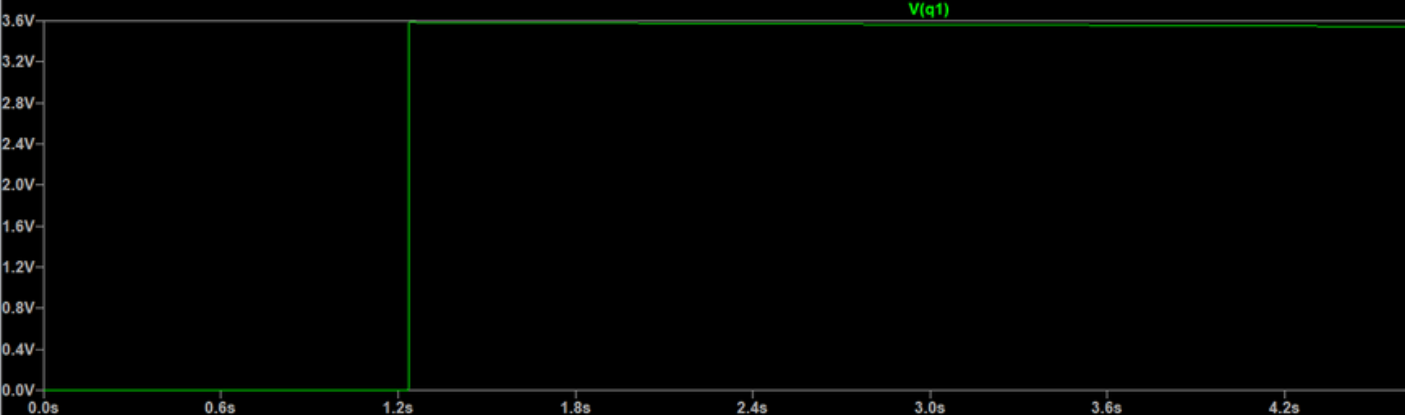

- Output Q reaches a stable ~3.3 V, enough to boot a Bluetooth node; storage sizing trades start-up time vs stability.

- Practical note: mechanical coupling dominates variance; small changes in ramp pressure/position noticeably affect available energy.

What I did

- LTSpice modeling & sweeps (Bennet, thresholds, storage).

- Bench measurements and consolidation into operating windows hitting the 3.3 V target.

- Recommendations: improved mechanical fixture, lower-drop diodes, and soft-start on the DC-DC stage.